1. The Critical Role of the Rectangular Expansion Joint

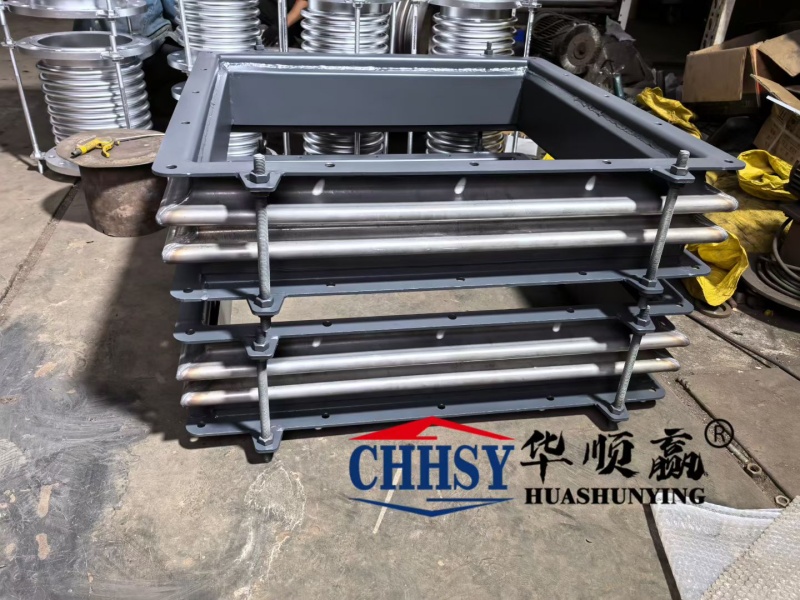

A Rectangular Expansion Joint, also known as a rectangular metal bellows or compensator, is an engineered component vital for the integrity and longevity of ductwork systems. Designed with a corrugated profile, this flexible element is specifically engineered to absorb movement and stress. Installing a Rectangular Expansion Joint between rigid ductwork and equipment (fans, AHUs, etc.) is a fundamental best practice for managing system dynamics.

2. Key Features and Benefits of Our Rectangular Expansion Joints

Our Rectangular Expansion Joints provide robust solutions for the most demanding applications. The core benefits include:

Superior Thermal Expansion Compensation: The primary function of our Expansion Joint is to safely absorb dimensional changes caused by temperature fluctuations in rectangular ductwork.

Effective Vibration and Noise Isolation: Significantly dampens vibrations and reduces noise transmission from mechanical equipment, protecting the system and environment.

Stress Relief from Misalignment: Accommodates initial installation offsets and structural settling, preventing harmful stress concentrations in the duct system.

Robust and Durable Construction: Manufactured from high-quality materials, our Rectangular Expansion Joints are built for long-term reliability under positive and negative pressure.

High-Temperature and Corrosion Resistance: Suitable for a wide range of environments, from standard HVAC to harsh industrial processes.

3. Applications: Where to Use Our Rectangular Expansion Joints

Our Rectangular Expansion Joints are versatile solutions for numerous applications:

HVAC Systems: Essential for connecting fans, air handling units (AHUs), and chillers to rectangular metal ductwork in commercial buildings.

Industrial Ventilation Systems: Critical in managing movement and vibration in factory exhausts, fume extraction systems, and power generation facilities.

Smoke Control Systems: Acts as a flexible link in smoke management ducts (when constructed from certified non-combustible materials).

High-Temperature Processes: Ideal for applications involving heat recovery steam generators (HRSGs), turbines, and industrial ovens.

4. Materials and Construction

We offer a range of materials to meet the specific requirements of your application:

Galvanized Steel: A cost-effective and durable standard for most general ventilation applications.

Stainless Steel (304, 316L): Offers superior corrosion and high-temperature resistance for harsh environments (chemical, marine, food processing).

Each Rectangular Expansion Joint is constructed with precision and features durable flanges (angle ring, tap-in, or blind) for a secure, airtight connection to the rectangular ductwork.

5. Installation and Maintenance Tips

Installation: The Expansion Joint must be installed in a neutral state. Do not stretch, compress, or twist it beyond its design limits during installation to ensure optimal service life.

Maintenance: Regular inspection for wear, fatigue, or corrosion is recommended to maintain the performance and safety of your Rectangular Expansion Joint.

Why Choose Our Rectangular Expansion Joints?

As a specialized manufacturer, we are committed to providing high-quality, reliable Expansion Joints that enhance the safety, efficiency, and durability of your duct systems. Our products are engineered to meet the rigorous demands of modern industrial and commercial ventilation.

Contact us today to discuss your project's specific movement compensation needs or to request a quote for our premium Rectangular Expansion Joints.